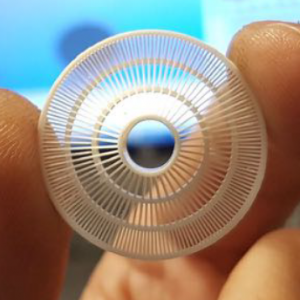

We always perform a feasibility study of a part before designing a plastic injection mould for it.

This includes a detailed review of all features of the part like wall sections, draft angles, feed point position, correct venting, ejectors location, etc.

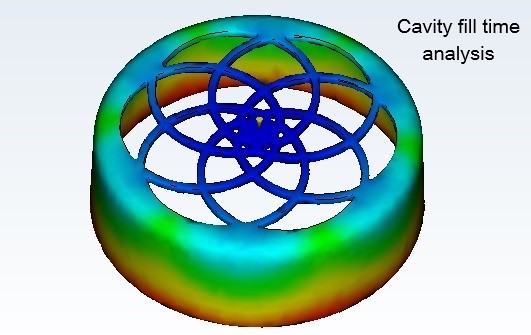

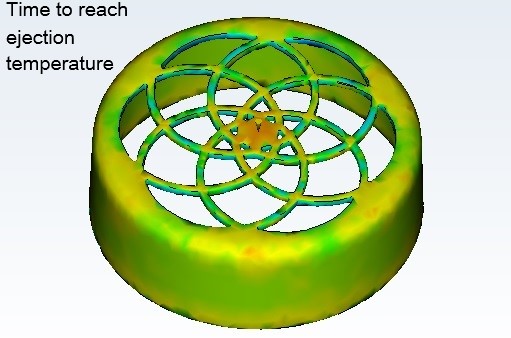

A flow simulation is also performed to eliminate possible issues during moulding process like short shots, flow lines, air traps, etc.

Some examples of the flow simulation: